AFDP is capable of conducting shelf life and biosafety validation studies with a variety of packaging equipment available for use in the Meat Safety and Processing Research Unit. Please note that this equipment is for pathogen research and it, along with materials that have come into contact with it, cannot be used outside the Meat Safety and Processing Research Unit.

Our packaging equipment:

- Multivac Tray Sealer T200

Output: 3 to 12 Trays/min

Tray size: Basic format 380 x 300 mm, can be divided up as required - Multivac C200 Packaging MachineThe C200 offers, efficient packaging, with a higher evacuation capacity.

It also offers additional options, however, including the ability to create Modified Atmosphere Packaging (MAP).

It is simple to operate and to clean, and delivers first class, consistent packaging results.Specifications; 18 language options, 150mm x 490mm x 355mm (H x W x D), vacuum pump Busch 21 m │/h

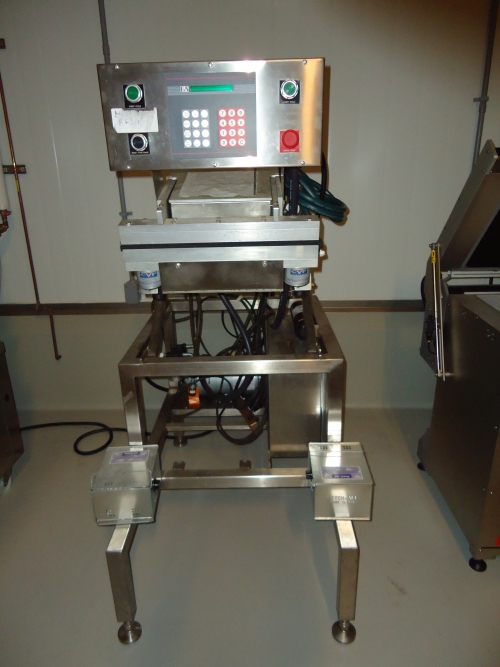

- CVP A-300 Fresh Vacuum packager (pictured)

- KOCH RM-571 Vacuum Skin Packaging MachineThe KOCH Intact RM571 provides a unique method for

creating retail-ready vacuum skin packages for all your finest products, including upscale steaks,

chops or seafood. This vacuum skin packaging system offers greater versatility by delivering an array

of packaging styles and tray sizes due to its ability to support film-to-tray, film-to-board and film-to-film applications.Specifications; dimensions 890mm x 1,105mm x 1,465mm (W x L x H), sealing area 560″ squared, 2 cycles/minute, weight 625 lbs