The 7,400 square-foot, containment level 2, Meat Safety and Processing Research Unit (MSPRU) is a one-stop shop for food safety research. As part of the university’s Agri-Food Discovery Place, it is a biosafety containment level 2 meat-processing facility that allows researchers to process meat with food-borne pathogens simulating industry conditions throughout the processing chain, including retail and consumer handling.

In this state-of-the-art facility that simulates an industrial setting, researchers, the meat- and food-processing industry, equipment manufacturers, ingredient and processing aid suppliers and government are able to carry out food safety and quality research and validation projects. The labs are ideally suited to enable clients to conduct research with products that represent the entire processing spectrum under industry, retail and consumer handling conditions. Research can include development and application of novel technologies to inactivate or inhibit the growth of microbial pathogens to improve food safety. Research expertise includes the impact of the microbiome on storage life and quality of food. The MSPRU provide the facility for meat and food processing industry, equipment manufacturers, ingredient & processing aid suppliers, academia and government to carry out food safety &quality validation projects in a state- of- art facility that simulates and industrial setting.

MSPRU facility Equipped with:

- Cargill Meat Solutions Cold processing Room

This temperature controlled room is equipped with all types of processing equipment including an

emulsifier, injector, tumbler, grinder, slicer, stuffer and a vertical cutter that serves as a bowl chopper, vacuum tumbler and bowl cooker. - Cargill Meat Solutions Thermal Processing Room

Equipped with smokehouse, steam kettle, two high pressure processors, convection oven, fryer, range and cook top. - Lilydale Controlled Storage Laboratory

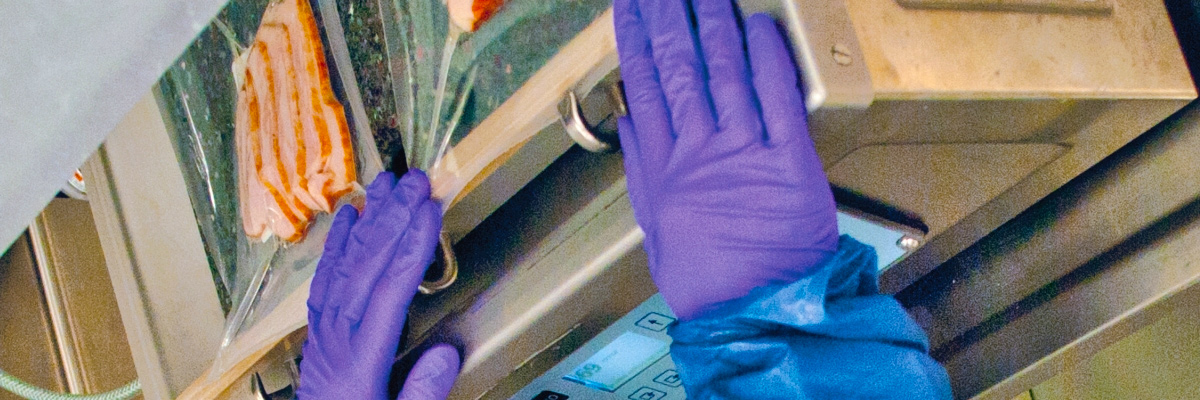

Includes three walk-in coolers, walk-in freezer, vacuum skin packager, modified atmosphere tray sealer, chamber vacuum packager and modified atmosphere packager. - Alberta Beef Producers Laboratory

Laboratory designed for testing of equipment. - Microbiology Laboratory

Full service microbiology lab equipped with modern instruments.

Our industry-driven applied research focuses on:

- Product safety and quality

- Shelf- life extension

- Application of novel technologies

- Process development

- Process and product validation

- Troubleshooting safety and quality problem.

Example areas of research or validation:

- To determine the effect of antimicrobials on the survival and growth of Listeria monocytogenes in products

- For processing your products with new ingredients to determine their effect on safety and quality

- To conduct 5-D challenge studies with Escherichia coli O157:H7

- To evaluate the microbiological effect of displaying a fully cooked food products at different temperatures

- To validate that the formulation of a food products will inhibit pathogen growth at different storage temperatures

- To evaluate the effect of high pressure processing on the products

- To determine the measurable growth of pathogens of concern in a particular food products at various temperatures

- To determine the effect of simulated retail display on the survival and growth of pathogens in products

- To evaluate the effect of processing a RTE meat with “natural” preservative – free curing systems on the growth of Clostridium perfringens.

Our Collaborators:

- Professor Lynn McMullen

- Professor Michael Gänzle

For more Information please contact:

Ross M S Lowe, MSc

Meat Safety and Processing Research Unit Lead

AFNS, University of Alberta

Building F-83, AFDP

6020 - 118 St, Edmonton, AB, T6G 2E1

(780) 492-4537