Fermentation Platforms

Industrial fermentation is the process by using microorganisms to make value-added products, including biomass, extracellular metabolites, intracellular components, and transformation of substrate. Fermented products have wide applications in food, pharmaceutical, chemical and general industry.

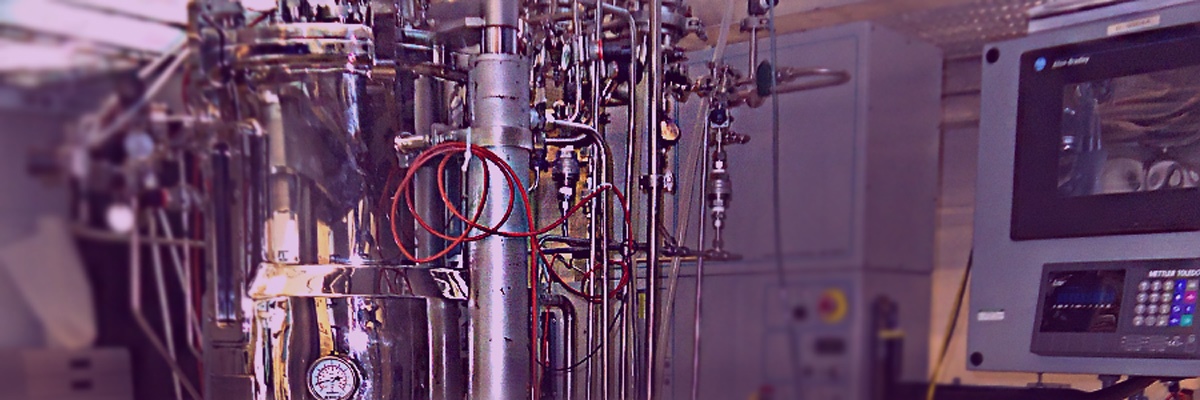

The Microbiology Laboratory and Fermentation Pilot Plant at AFDP are well equipped to support product and process development in submerged fermentation from bench top to 1,500L bioreactor. We provide services to academia and Industrial clients in optimization and scale up of industrial fermentation processes.

Our fermentation facility is equipped with:

- Three identical 5L fermenters can be used simultaneously to optimize process parameters and media optimization

- One 140L and one 1,500L fermenters with PLC control to monitor and control of DO, pH, temperature, airflow, agitation for scale up or scale down

- Fermenters can work in batch or fed-batch mode

- Fully equipped Microbiology Laboratory to support fermentation project

- Pilot-scale downstream processing equipment for cell disruption, centrifugation, filtration, membrane filtration, protein purification, solvent extraction, evaporation, spray drying, lyophilization and so on

- Analytical capabilities Including HPLC, GC, chromatography, biochemistry analyzer, etc.

- Final product analysis, including moisture, water activity, appearance, etc.

- Access to other laboratories at the University of Alberta for additional testing

Typical projects of Industry driven applied research in fermentation:

- Work with biosafety level 1 microorganisms, including bacteria, yeast, fungi, and microalgae fermentation

- Media optimization

- Scale up and/or scale down to 140L - 1,500L bioreactor

- Probiotics and food or feed Ingredients

- Biomass to ethanol conversion

- Bio-material and bio-process development for both upstream and downstream processing

Contact us:

Unit Lead: Fermentation Laboratory

Jiancheng Qi, MSc, CFS, P.Eng.

Agri-Food Discovery Place

Dept. of Agricultural, Food & Nutritional Science

Phone: 780.492.3104

Email: jiancheng.qi@ualberta.ca